For more concrete batch Plant technical documents, Download free in PDF form !!

concrete batch Plant

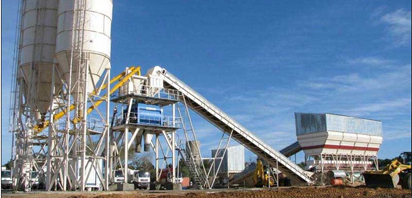

A concrete plant, also known as a batch plant or batching plant or a concrete batch Plant, is a device that combines various ingredients to form concrete. Some of these inputs include sand, water, aggregate (rocks, gravel, etc.), fly ash, potash, and cement. There are two types of concrete plants: Dry mix plants and Wet mix plants. A concrete plant can have a variety of parts and accessories, including: mixers (either tilt-up or horizontal or in some cases both), cement batchers, aggregate batchers, conveyors, radial stackers, aggregate bins, cement bins, heaters, chillers, cement silos, batch plant controls, and dust collectors (to minimize environmental pollution). The center of the concrete batch Plant is the mixer. There are many types of mixer like Tilt, Pan, Planetary, Single Shaft and twin shaft mixer. The twin shaft mixer can ensure an even mixture of concrete and large output, while the tilt mixer offers a consistent mix with much less maintenance labor and cost

haomei concrete batching plant is composed of aggregate storing and weighing system, control system,concrete mixer, cement and power material weighing system, additive weighing system, water weighing system, screw conveyor, cement silo.

Main Configuration Table of HZS90 concrete batch Plant

| Item | Configuration | Specification, model | Producing area | Qty | Unit |

| 1、Proportioning system PL2400 |

Aggregate bin | each bin 13m3 | China | 4 | piece |

| Aggregate metering bin | China | 4 | piece | ||

| Weighing sensor | America | 4 | set | ||

| Aggregate output belt conveyor |

800 mmwidth (with cleaner) |

China | 1 | piece | |

| Length:32000mm | |||||

| Cylinder | SI-100-300 | TAIWAN | 12 | piece | |

| Vibrator | MVE200/3 | Italy | 4 | piece | |

| Vibrator | MVE100/3 | Italy | 2 | piece | |

| Frame | China | 1 | piece | ||

| 2、Aggregate hoisting system | Flat belt | 1000mmwidth,18° | China | 1 | piece |

| Length: about70000mm | |||||

| Motor | 30KW | China | 1 | piece | |

| Axes-mounted reducer | ZGY625.90 | China | 1 | piece | |

| Upper and lower support roller | China | 1 | set | ||

| Cleaning device | China | 1 | set | ||

| Tightening device | China | 1 | set | ||

| Machine frame | Double walkway | China | 1 | set | |

| Color armor plate casing | China | 1 | set | ||

| 3、Mixing main engine | JS1500Mixing tank body | China | 1 | piece | |

| Reducer | 309R2FZ | Italy | 2 | piece | |

| Bonfiglioli | |||||

| Motor | 30KW | China | 2 | piece | |

| Discharge system | China | 1 | set | ||

| Lubricating system | China | 1 | set | ||

| Shaft end main sealing parts |

China | 1 | set | ||

| 4、Mixing main building | Main building support leg |

China | 1 | set | |

| Finished receiving hopper | China | 1 | piece | ||

| Mixing floor | China | 1 | piece | ||

| Metering floor | China | 1 | piece | ||

| Transition bin | China | 1 | piece | ||

| Cylinder | SI-125-200 | China | 1 | piece | |

| Vibrator | MVE100/3 | Italy WAM | 2 | piece | |

| Building top | China | 1 | piece | ||

| Stair walkway | China | 1 | set | ||

| Exterior casing | 75mmWarming plate | China | 1 | set | |

| Dust collector system | SCM-10 | SICOMA | 1 | set | |

| High pressure cleaning system | SL40A | China | 1 | set | |

| 5、Water weighing system | Water weighing box | 450kg | China | 1 | piece |

| Weighing sensor | America | 3 | piece | ||

| Butterfly valve | SICOMA | 2 | piece | ||

| Water storage box | China | 1 | piece | ||

| Liquid indicator | TAIWAN | 1 | set | ||

| Water pump | China | 2 | piece | ||

| Pipeline | China | 1 | set | ||

| 6、Cement metering system | Metering bin | 900kg | China | 1 | piece |

| Weighing sensor | America | 3 | piece | ||

| Butterfly valve | SD300 | SICOMA | 1 | piece | |

| Vibrator | MVE60/3 | Italy WAM | 1 | piece | |

| Weighing bin | America | 3 | piece | ||

| Butterfly valve | SD250 | SICOMA | 1 | piece | |

| Vibrator | MVE60/3 | Italy | 1 | piece | |

| 7、Additive weighing system | Additive weighing box | 45kg | China | 1 | piece |

| Weighing sensor | America | 1 | piece | ||

| Butterfly valve | GTB671X-10-50 | China | 3 | piece | |

| 剂箱Additive box | China | 2 | piece | ||

| Liquid indicator | China | 2 | set | ||

| Additive pump | China | 2 | piece | ||

| Pipeline | China | 2 | set | ||

| 8、Pneumatic system | Air compressor | TAIWAN Fusheng | 1 | piece | |

| Solenoid valve | TAIWAN AIRTAC | 1 | set | ||

| Pipeline system | TAIWAN AIRTAC | 1 | set | ||

| Air storage | CQG-0.1 | Yantai | 2 | piece | |

| 9、Electric control system | Strong electric cabinet | China | 1 | piece | |

| Weak electric cabinet | China | 1 | piece | ||

| Control console | China | 1 | piece | ||

| Control room | 8m2 | China | 1 | piece | |

| Industrial computer | IPC810 | EVOC | 2 | piece | |

| LCD | 17” | Lenovo | 2 | piece | |

| Contactor | Schneider/ABB | 1 | set | ||

| Circuit breaker | Schneider/ABB | 1 | set | ||

| Mini relay | APT/OMRON | 1 | set | ||

| PLC | OMRON | 1 | set | ||

| UPS | TG500 | SANTEK | 2 | piece | |

| Air condition | 1.5 | Midea | 1 | piece | |

| Electric control assistant component |

China | 1 | set | ||

| Monitor | SP-14 | SUNSPO | 2 | piece | |

| Camera | SP-942 | SUNSPO | 2 | piece | |

| Printer | KX-P1121 | Panasonic | 1 | piece | |

| Connecting cable and accessory |

China | 1 | set | ||

| 10 | Warm System | China | 1 | set | |

|

The following cement silo is also called powder cans, and screw machine is the freedom to choose the client to the project, customers can buy don't buy, if buy, decide to purchase quantity |

|||||

| 11、Powder supply system (User choice) |

Cement screw conveyor | φ273 | China | set | |

| Powder pot | 100T | China | set | ||

So choose what kind of Batching Plant. If the water conservancy project, must choose the forced mixing machine. In addition, should also be based on the type of material selection can be mixed concrete batch Plant and storage bin.

With these two parameters to select the concrete batch Plant with a large number of specifications. The total amount of concrete is M; the number of concrete pouring days is T; the number of working hours per day is H; the utilization coefficient is K, then we should choose the mixing station's specification X=M/ (T*H*K), where K is 0.7-0.9. In the selection of finished concrete transport situation. Such as: is a direct pumping or transport vehicles. The volume of transport vehicles is also an important basis to determine the type of mixing station.

In the choice of the purchase of concrete mixing Plant, should fully consider the construction of the object and the influence of the environment, so as to ensure the smooth construction and construction quality. In the following case we suggest you had better prepared against want.

If the concrete pouring demand is large enough, and there is no alternative concrete batch Plant nearby, it is suggested to choose two concrete batch Plants with the small capacity.

If the transportation condition of construction site is not convenient and it usually takes a lot of time for maintenance personnel on the path, customers had better choose two small scale concrete batch Plants with the same specification or get other conditions ready enough to ensure the smooth construction progress.

If the construction sites are scattered and the distance between each other is not very far, so that the transportation radius of concrete pump truck does not exceed half an hour’ drive and the transportation time of tilting cart is within 10 minutes, you had better choose a concentrated concrete batch Plant to improve its use ratio and construction economic benefit.

In general, the structure of small batching plant is relatively simple and so is its control system. Therefore, there are fewer requirements on operation and maintenance personnel; while the requirements of the large concrete batch Plant with complicated structure and high automation degree will be higher.

.jpg)

.jpg)

Generally speaking, manufacturers have mature production configurations, such as specification, quantity, variety, etc. You can also put forward your special requirements when choosing a suitable concrete batch Plant.