For more concrete batch Plant technical documents, Download free in PDF form !!

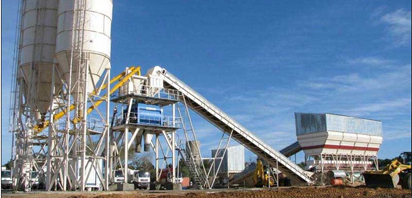

concrete batch Plant

Installation Preparations what concrete batch Plant

concrete batch Plants installation is the greatest guarantee the safe use later, so preparatory work prior to installation we also need to do the full job, then how will the concrete batch Plants installation to maximize the potential, we must do the rational and bar below haomei to resolve concrete mixing station preparations have?

- 1, the first given by the manufacturer in accordance with the concrete batch Plant installation foundation plans, and prepare the ground and embedded. Installed base must be solid, consistent architectural design specifications.

- 2, good planning construction of access roads, temporary schwing concrete placing booms bridge, wharf and stockpiling area, and undertake leveling, not only did water, electricity, land leveling.

- 3, assembly concrete batch Plants hoisting equipment, such as cranes, tower vehicles, the installation process is not only to choose the right position, the more important is that we must use professional operators to install.

- 4, concrete batch Plantis mainly responsible positions in their own due diligence to ensure that every job acceptance, the only way to ensure safe and efficient work. Security is no small matter concrete mixing station, so we must not relax, only to lay a good foundation for a solid backing, so in order to produce efficiently must be taken seriously for each job.

To install a concrete batch Plant correctly is very important to productivity of concrete batch Plant. Here are some installation steps to install a concrete batch Plant

Installation steps of concrete batch Plant

- (1) Installation of finished material adhesive tape conveyor Expand finished material adhesive tape conveyor at its bends and then put frame on the base. Next, link legs with conveyor as well as the bracing piece and lifting lug. Thirdly, lift the front of conveyor and like legs and bracing piece well. Finally, fasten anchor bolt of legs well.

- (2) Installation of host and powder batching system Sling the rack of host and put it on the base. Then fasten its anchor bolt.

- (3) Installation of storage bin Sling storage bin and rise up legs. Link walking board, ladder and storage bin well.

- (4) Installation of aggregate dosing machine sling aggregate dosing machine to put it on the base. Link blank as well as heightening plate and blank. Next, expand aggregate conveyor. Link rack to make motorized pulley align cover hole center of concrete mixer. Finally, fasten anchor bolt.

- (5) Installation of cement silo Assemble all parts of cement silo well on the ground and then lift cement silo. Make support of it orient to power batching system and then fasten it. In the end, fasten anchor bolt.

- (6) Installation of screw conveyor Sling screw conveyor. Link spherical hinge of screw conveyor and discharging outlet of cement silo well to make discharging outlet align feeding inlet. Then link conveyor and lifting lug of cement silo by steel wire rope. Finally, fasten anchor bolt.

- (7) Lift water pump to a proper position and link output pipe well.

- (8) Put air compressor at one side of storage bin. Link exit of air compressor with entrance of gas control box. Lead exit of gas control box to air tube of cement silo.

After completion of the concrete batch Plant produce what issues need attention

concrete batch Plant will be some unforeseen problems in production, it requires staff each position must be serious and responsible, to ensure that the production of some minor problems can be solved in time, but after the completion of production requires concrete batching station clean-up work, so as to ensure the efficient production next. So today we take a look at the concrete batch Plant After production problems which need attention.

- 1, frozen season, was completed pump should be exhausted, additional coolant pump, water tank, additional agent tank, water, additives in the pipeline residual water, additives to prevent damage to Diesel concrete pump the pump and tubing, and start the pump additional coolant pump operate for 1-2 minutes.

- 2, clean the batching tank inside and outside wall fouling, the discharge mouth, concrete residue agitator shaft and discharge door, where rinse with water, if necessary, add a small amount of stone and water, stirring for several minutes release. Water for washing cars, and for the additional agent tank system.

- 3, the lubrication points are located out door shaft mixer, each hopper and weighing Doumen shaft, tape transport, machine roller, roller, roller bearings, drive chains, screw shaft, the lower bearing and host large gear, etc.

- 4, adjusted when checking blades, scraper, stirring arms and other necessary clearance for wear or replaced; vibrators without loosening bolts; check the electrical contact device; static and dynamic contact relay damage and burnout. These are concrete batch Plant production work after the completion of the inspection and maintenance issues, although more complicated, but we must make these basic smooth production work can only be assured of.